The apparel manufacturing process begins with an idea and ends with a finished garment ready for market. Turning a sketch into reality requires technical skill and a sharp sense of market demand. Each step is designed to ensure the piece meets quality expectations. Keep reading to learn more about the main steps in the garment manufacturing process.

Fabric preparation

Before garments are produced, fabric undergoes a detailed preparation stage. The way this is managed has a direct impact on durability, color depth, and overall finish. Each decision – whether in fiber choice, weaving method, or textile dyeing – affects how the final garment looks and performs. When handled correctly, the fabric develops the strength, consistency, and texture needed to stand up to everyday use and maintain its appearance over time.

1. Fiber selection and preparation

The first step is choosing fibers that deliver the qualities a brand wants. Work often begins with a fabric supplier, who provides options ranging from cotton and polyester to wool and silk. Each fiber has distinct characteristics: cotton is breathable, while polyester adds strength and resilience. Wool retains warmth, and silk gives a refined finish.

Before spinning, raw fibers are cleaned thoroughly to remove dirt and impurities. Blends like cotton with polyester are also created to balance softness with durability, giving manufacturers flexibility in meeting specific design and performance goals.

Moisture levels are also adjusted to around 50-60% relative humidity for cotton. This prevents static, minimizes breakage, and helps the fibers spin evenly.

2. Spinning the yarn

Once prepared, fibers are carded; that is, aligned into a continuous strand called a sliver. The sliver is twisted into a thinner roving and spun tighter to produce yarn with the desired thickness and strength.

Mills can control yarn weight and performance by adjusting spinning speeds and twist levels. The finished yarn is wound onto spools or cones for storage.

3. Fabric formation

Yarn is made into fabric using several techniques:

- Weaving places warp and weft threads at right angles on a loom to produce a firm, balanced cloth.

- Knitting relies on needles or machines to build loops that link together, creating a fabric with natural stretch.

- Non-woven materials take a different route: loose fibers are layered and bonded through heat, pressure, or adhesives. This stage is often described as the key fabric-to-apparel step, as yarn becomes usable fabric.

4. Dyeing or printing

Color and pattern bring fabric to life. In textile dyeing, materials can be treated in batches, passed continuously through dye baths, or dyed after the garment is completed.

Printing, however, applies surface designs instead of coloring the whole textile. Techniques like screen printing, digital printing, or heat transfer add bold patterns to fine logos.

Apparel manufacturing process

Turning fabrics into finished garments is a structured yet highly creative process. Each stage builds on the last, with checks to ensure durability and market-ready quality.

1. In-house sampling

Production begins in the design room, where teams study market trends and draft sketches by hand or computer.

These ideas are translated into detailed tech packs, graded patterns, and size sets, essential pre-production documents that guide cutting and construction. In-house sample rooms are then used to create prototypes.

Each cut piece is checked carefully for fit points approval, and fabrics are inspected for flaws before moving forward. This stage ensures the design, pattern, and selected materials produce the fit and finish intended.

2. Cutting and marking

After the sample is approved, fabric is laid out in layers and marked with pattern guides. Many workshops use CAD systems to direct automated cutters, producing panels with consistent precision. Sleeves, bodices, and other parts are measured to exact dimensions, allowing maximum use of fabric while minimizing waste.

3. Sewing

Panels are then joined by trained machinists, with stitching methods chosen to match the properties of the fabric.

Straight stitches hold basic seams, zigzag stitches give elasticity to stretch fabrics, while buttonhole stitches reinforce fastenings.

Choosing the right thread and needle is critical; light cotton, for example, requires a fine needle and matching thread.

Operators perform seam inspections throughout this stage to ensure strong, uniform stitching. Early checks identify issues such as skipped stitches or uneven tension before production continues.

4. Trimming

Loose threads and fabric scraps are cut away to give the garment a tidy finish. If there are exposed edges, they are secured with overlocking or binding, especially at points that take strain. At this stage, inspectors also review the seams to confirm they are neat and defect-free.

5. Embellishment and printing

The garment can now be personalized or branded. Common additions include embroidery, screen prints, appliqué, and foil designs.

Functional items such as zippers, buttons, snaps, and labels are also fixed in place. Pockets must align correctly, and fastenings are reinforced so the garment remains durable and wearable.

6. Pressing and finishing

Pressing sets the garment’s final shape. Press teams use industrial irons, steam tunnels, and spot presses to smooth seams, open pleats, and lock creases at the correct temperature and dwell time.

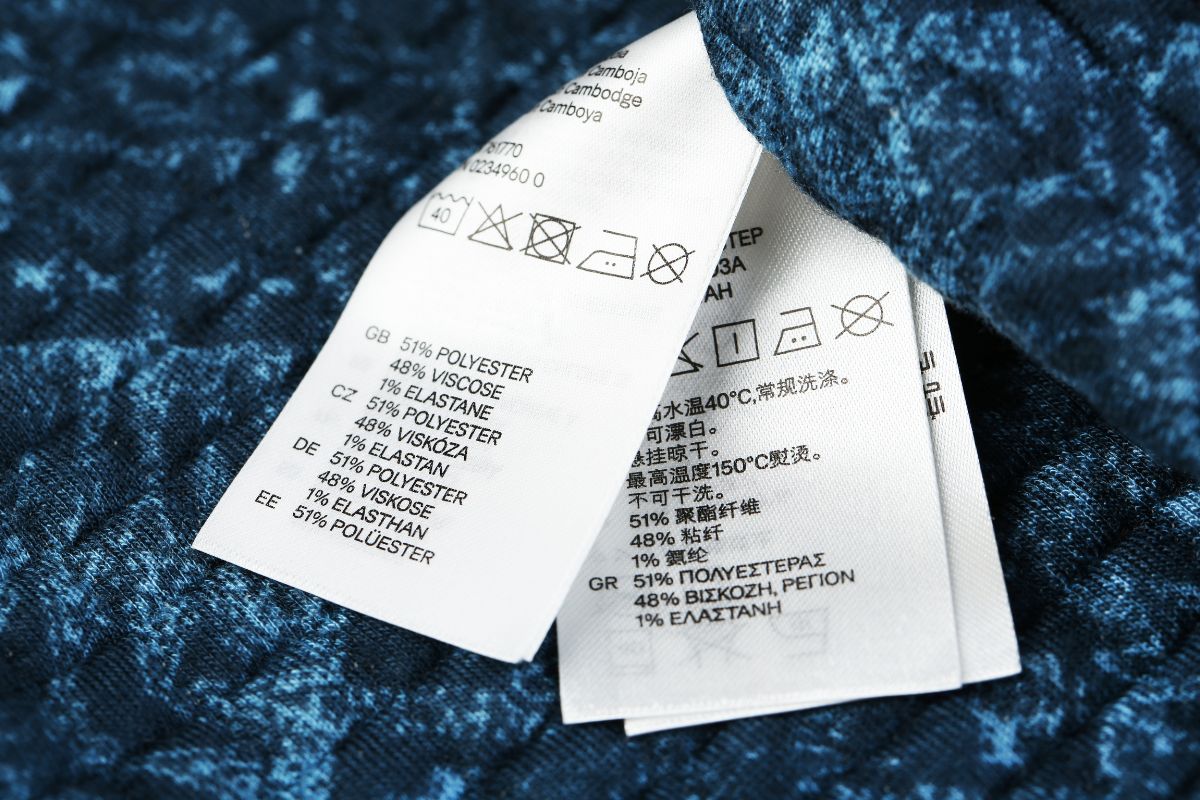

Finishing details for clothes like stitch lines are also flattened, collars and cuffs are shaped, and shine is prevented with covers or vacuum tables. The next line is labels and tags; brand, size, and care are fixed exactly as the tech pack specifies, with placement tolerances checked in millimeters.

Before goods move to packing, inspectors perform a final quality check. They look for loose threads, skipped stitches, puckering, shade variation, print alignment, and off-spec measurements. These quality control procedures form a critical safeguard. They help brands maintain consistency and reputation.

Capital World Group’s strict quality control process, certified to ISO 9001 and audited under Higg FEM, amfori BSCI, SLCP, and other standards, delivers consistent, defect-free output.

7. Packing

At the packing stage, pieces are folded to the approved template, wrapped in tissue where required, sealed in polybags with size stickers and desiccants, and sorted by size/color into barcoded cartons.

The packing list, commercial invoice, and certificate of origin are prepared; cartons receive SSCC labels and are palletised to spec. This post-production stage maintains traceability, protects the finish in transit, and readies orders for global shipment.

8. Shipping

Before leaving the factory, shipments are checked against the order for accuracy. Cartons are sealed and labelled, then exported to ports or airports.

Whether delivered FOB (Free On Board) or through managed logistics, clear documentation ensures each order arrives at its intended destination, completing the garment’s journey from design sketch to retail floor.

What is garment manufacturing?

At its core, the apparel industry connects creative design with large-scale production. It begins with sketches and market research, moves through fabric sourcing and textile production, and ends with fully assembled garments ready for consumers. This sequence links designers, mills, and factories into one continuous chain that fuels fashion trends and global trade.

The economic impact of this sector is enormous. The global apparel industry was valued at $1.84 trillion in 2025, representing about 1.65% of world GDP. Projections show a compound annual growth rate (CAGR) of roughly 2.8% between 2025 and 2028, underlining the resilience of clothing production even in a competitive global economy.

Within this growth, women’s apparel plays the leading role. In 2024, the segment generated an estimated $930 billion and is forecast to exceed $1 trillion by 2027. Dresses, blouses, skirts, and other categories dominate retail shelves, making womenswear the driver of expansion.

In practical terms, garment manufacturing encompasses all the clothing production steps: fiber preparation, spinning, weaving or knitting, sewing, embellishment, finishing, trimming, packing, and shipping.

Each stage adds value and quality, transforming raw fiber into polished products. For fashion brands, mastering these processes ensures reliable supply chains, consistent quality, and the ability to meet market demand on time.

How to optimize the garment manufacturing process?

Many brands struggle with shipping delays and extra costs when materials and production steps happen at distant locations. The solution is to choose a fully managed production workflow run by a trusted garment manufacturer.

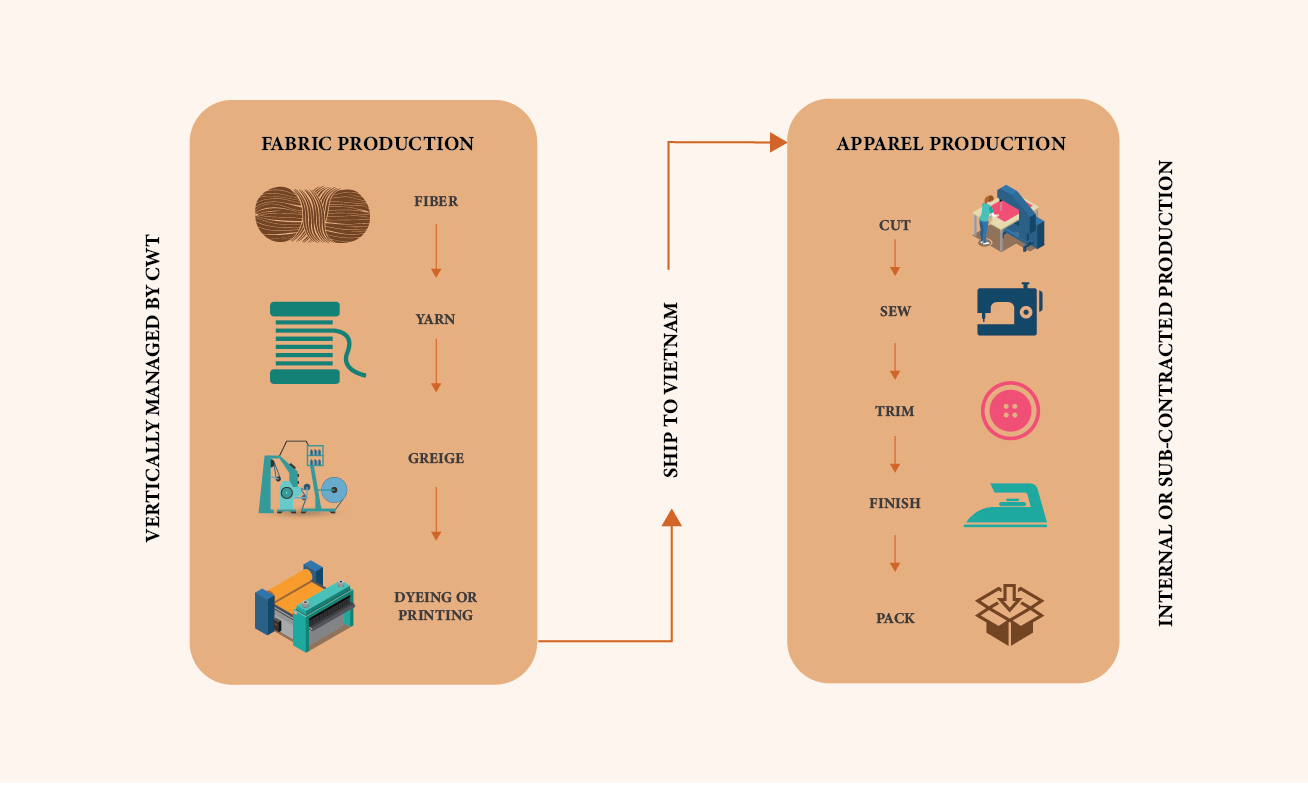

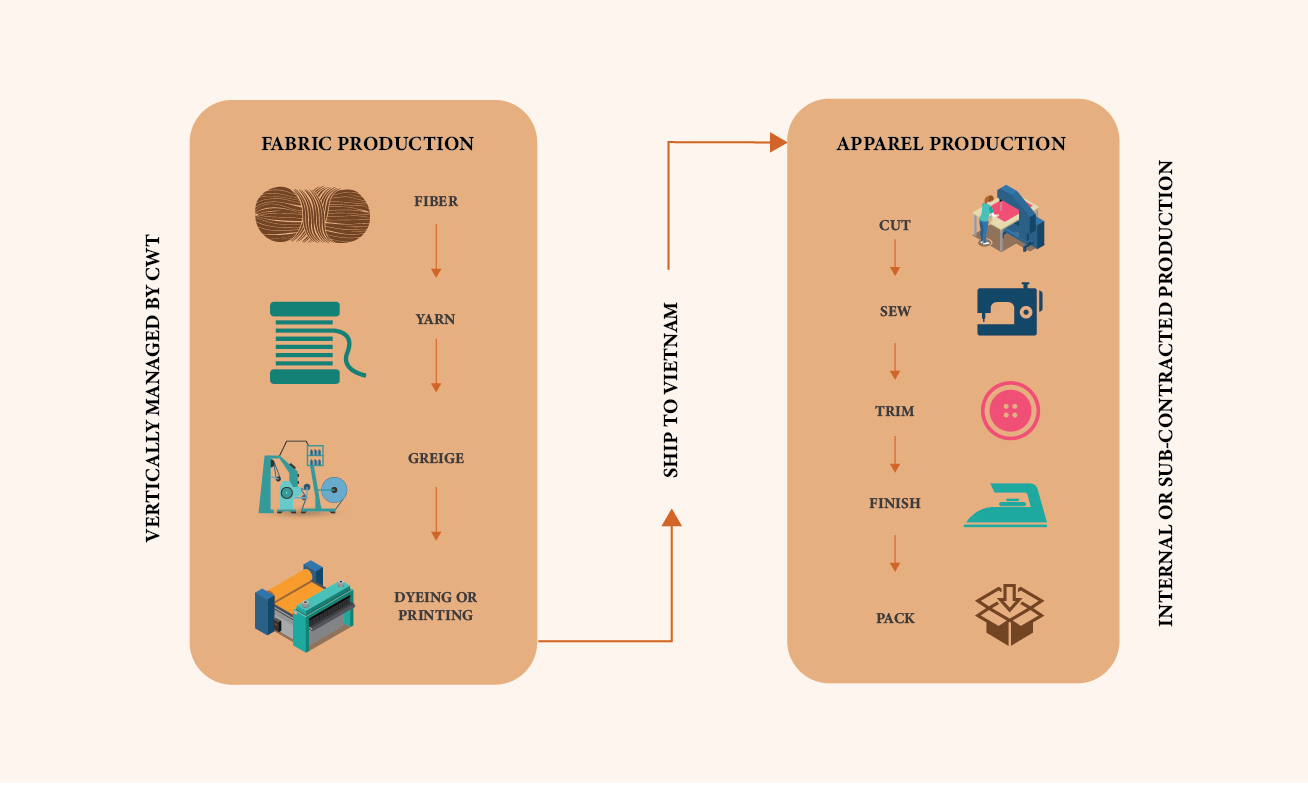

An example is Kiara Garments Factory of Capital World Group, which follows a fibre-to-fashion, full-package model. This vertical management compresses lead times and maintains in-line QA/QC at each step, thanks to in-house development and owned production capacity.

Capital World Group maintains a vertically integrated supply chain system that ensures predictable timelines and consistent apparel quality. Capital World Group targets brands seeking a Vietnam apparel manufacturer with end-to-end supply-chain control through its Kiara Garments Factory.

Additionally, the country’s skilled workforce and consistent quality have attracted major global brands. Many well-known labels source here, including Nike, Adidas, H&M, Lululemon, and Uniqlo.

Additionally, the country’s skilled workforce and consistent quality have attracted major global brands. Many well-known labels source here, including Nike, Adidas, H&M, Lululemon, and Uniqlo. This “China Plus One” diversification trend is driven by China’s labor costs nearly doubling (e.g., urban garment wages averaging $500 – 650/month vs. $192 in Vietnam). Ongoing trade tensions (such as US tariffs on Chinese exports) have further pushed production to Southeast Asia. So, while China is one of the top clothing manufacturing countries by output, it is focusing more on higher-value and technical textiles at home.

This “China Plus One” diversification trend is driven by China’s labor costs nearly doubling (e.g., urban garment wages averaging $500 – 650/month vs. $192 in Vietnam). Ongoing trade tensions (such as US tariffs on Chinese exports) have further pushed production to Southeast Asia. So, while China is one of the top clothing manufacturing countries by output, it is focusing more on higher-value and technical textiles at home. However, importing much of their raw materials from China or Vietnam can extend lead times, and the industry still operates on a smaller scale than major regional players. In response, more producers are securing compliance and sustainability certifications to satisfy buyer requirements.

However, importing much of their raw materials from China or Vietnam can extend lead times, and the industry still operates on a smaller scale than major regional players. In response, more producers are securing compliance and sustainability certifications to satisfy buyer requirements. The US’s strengths include technical textiles, premium denim, athletic wear, and garments made with skilled labor and advanced technology. Many brands also use nearshoring to Mexico or Central America to stay competitive in a fast-moving market. However, the US also

The US’s strengths include technical textiles, premium denim, athletic wear, and garments made with skilled labor and advanced technology. Many brands also use nearshoring to Mexico or Central America to stay competitive in a fast-moving market. However, the US also