In the garment industry, the layout of machines and workstations plays a critical role in optimizing workflow. A well-planned sewing line ensures a smooth material flow, minimizes handling time, and enhances production efficiency. Proper sewing line design allows operators to work efficiently with fewer interruptions, improving productivity, quality, and consistency across the garment manufacturing process.

What is a sewing line?

A sewing line refers to the structured arrangement of sewing machines, workstations, tools, and materials in a production area. The purpose of this setup is to create a seamless flow of materials through each operation with minimal backtracking or waiting.

By arranging workstations strategically, factories can streamline the production sequence, balance operator workloads, and increase output. An efficient sewing line reduces lead time, minimizes fabric waste, and strengthens coordination across departments.

Types of sewing line layouts

Different sewing line layouts are designed to support specific production needs, factory conditions, and garment types. The following layouts represent the most commonly used sewing line configurations in garment manufacturing.

1. Straight Line Layout

The straight line layout arranges workstations in a single sequential flow, allowing garments to move directly from one operation to the next. It delivers stable output through specialization but offers limited flexibility when styles or volumes change.

Key characteristics

- Linear workstation arrangement with fixed operation order

- Specialized operators handling single or limited tasks

- High work-in-progress (WIP) compared to flexible layouts

Best used for

- High-volume, repetitive styles

- Basic garments with standardized operations

- Long production runs with stable demand

2. U-Shaped Layout

The U-shaped layout positions machines in a U formation, enabling operators to work closer together and handle multiple operations if needed. This structure improves communication and responsiveness, supporting better line balancing and production flexibility.

Key characteristics

- Shorter walking and material handling distance

- Easier supervision and faster problem-solving

- Supports multi-skilled operators

Best used for

- Small to medium production runs

- Styles requiring frequent adjustments

- Lean and efficiency-focused sewing lines

3. S-Shaped Layout

The S-shaped layout follows a curved production path, guiding garments smoothly through extended sewing sequences. It maintains continuous material flow while adapting to factory floor constraints, reducing backtracking and unnecessary movement.

Key characteristics

- Curved workflow with continuous progression

- Balanced workload across longer sewing sequences

- Improved flow without strict linear constraints

Best used for

- Long or complex operation sequences

- Factories with irregular or segmented floor layouts

- Medium to high-volume production

4. L-Shaped Layout

The L-shaped layout arranges machines in two perpendicular rows, allowing production flow to turn efficiently at a right angle. It supports smooth material movement while making effective use of corner spaces and constrained factory areas.

Key characteristics

- Perpendicular workstation arrangement

- Reduced congestion at operation handoff points

- Efficient utilization of narrow or corner spaces

Best used for

- Production floors with columns or physical restrictions

- Medium-volume garment production

- Lines requiring clear operation segmentation

4. Cellular Layout

The cellular layout divides sewing operations into small, self-contained units where teams focus on specific garment components or subassemblies. This structure enhances quality ownership and reduces internal transportation but requires skilled and well-coordinated operators.

Key characteristics

- Dedicated teams within each production cell

- Minimal material movement between operations

- Strong accountability for quality and output

Best used for

- Complex garments with multiple subassemblies

- Quality-sensitive styles

- Flexible production environments with skilled labor

5. Crossover Layout

The crossover layout uses intersecting production paths that allow operators and materials to cross efficiently without disrupting workflow. It maximizes floor utilization in dense production areas but requires disciplined process control to avoid congestion.

Key characteristics

- Intersecting material and operator movement paths

- High operator density within limited space

- Flexible routing between operations

Best used for

- Compact factory floors

- High-capacity sewing areas

- Facilities prioritizing space efficiency

6. Modular Layout

The modular layout groups machines so small teams of operators can collaboratively complete multiple operations. It supports lean manufacturing by reducing idle time and enabling rapid style changes, making it ideal for fast-response and fashion-driven production.

Key characteristics

- Multi-skilled operators working in teams

- Short material travel distances

- High adaptability to style changes

Best used for

- Short production runs and small MOQs

- Multiple styles running in parallel

- Fashion and quick-turn apparel production

Sewing line checklist for garment factories

Each sewing line has its own use and suitable for different purposes, products and designs. Check the following list to determine on the best layout for your factories:

|

Sewing lines |

When to use |

| Straight line | For one style with large quantities; fastest for long, steady runs. |

| U-Shaped line | For a few styles; promotes easy communication and quick problem-solving. |

| S-Shaped line | For long production sequences; prevents congestion and blockages. |

| L-Shaped line | For floors with columns or obstacles; fits tight spaces while maintaining flow |

| Cellular line | For complex garments with many components; teams handle sections before joining. |

| Modular line | For frequent style changes and short runs; supports one-piece flow. |

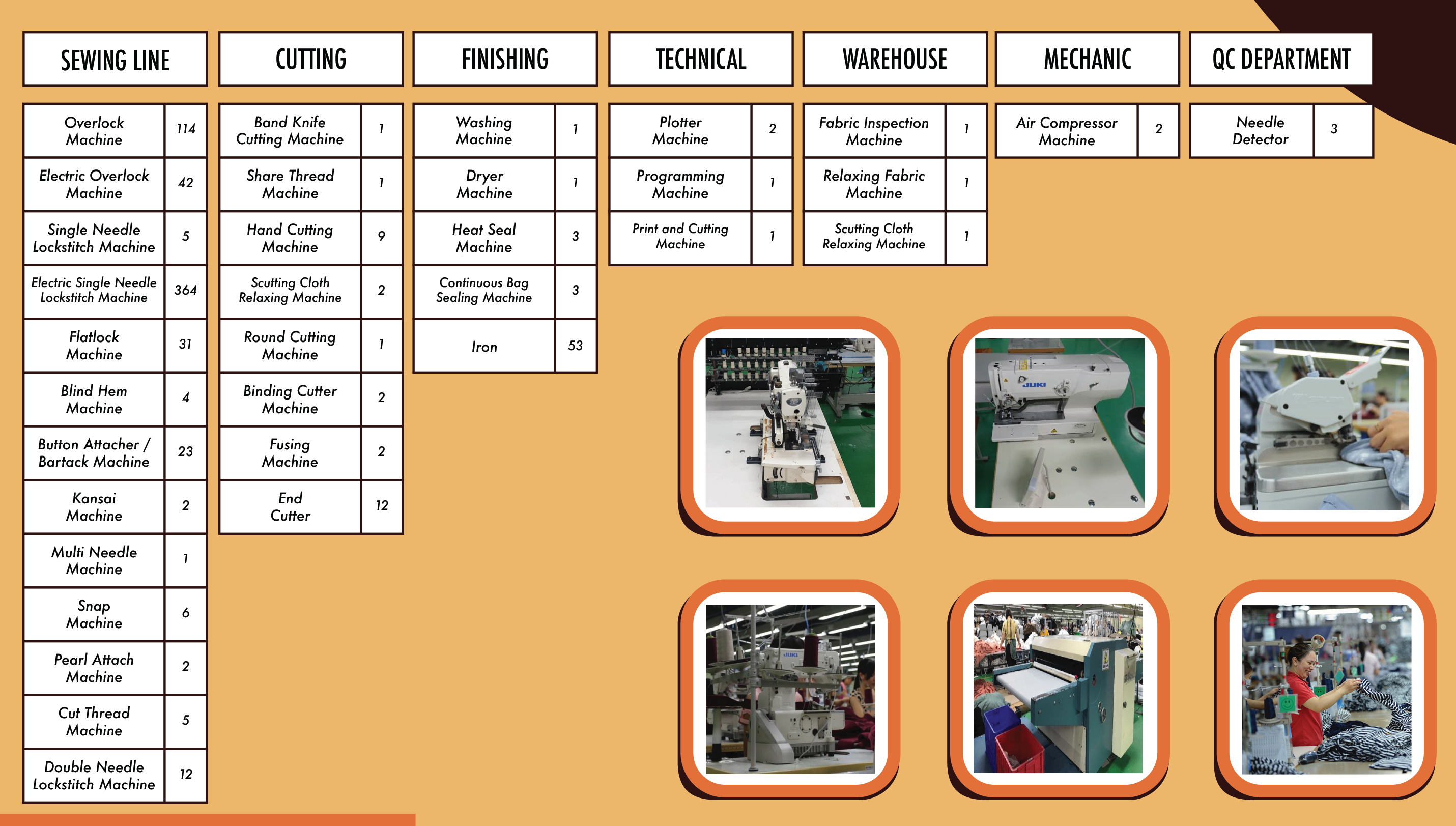

By utilizing a vertically integrated production model, Capital World Group consolidates key garment manufacturing stages – from pattern making and cutting to sewing line layout, finishing, and quality assurance – into a single, cohesive system. This comprehensive system ensures that the overall production flow is tightly controlled and highly adaptable, which in turn allows each sewing line to be independently optimized for maximum speed, accuracy, and cost efficiency.

This vertical management structure supports real-time coordination between departments, reduces production delays, and ensures each seam and stitch meets international standards.. Explore our vertical management model to learn how Capital World Group delivers a fully controlled supply chain that enhances flexibility and minimizes production costs.