Many garment brands face challenges with outsourced manufacturing, defects, late deliveries, or ethical lapses that can lead to costly recalls and damaged trust. Capital World Group (CWG) addresses this pain point as a Vietnam-based ladies’ wear manufacturer with fully integrated production. By implementing robust QC procedures at every stage, from fabric sourcing to final packaging, CWG ensures each garment meets spec and global standards.

Why are quality check procedures important in garment manufacturing?

A single quality slip in fashion manufacturing can damage a brand’s reputation and cause costly delays. That’s why quality check procedures are a strategic safeguard.

- Ensure products meet specifications: Thorough inspections verify garments match the original design and technical specs.

- Verify measurement, fit, and appearance: Inspectors confirm size, color, shape and quality, measuring dimensions and checking colors for accuracy.

- Reduce waste and cost: A garment’s quality procedure catches defects early, cutting rework and preventing wasted materials and labor.

- Save time and ensure on-time delivery: In-process QC prevents delays by fixing issues before production ends.

- Build trust and long-term relationships: Consistent quality strengthens client and customer confidence, fostering lasting partnerships.

Capital World Group’s standard QC procedures

As a trusted women’s clothing manufacturer in Vietnam, Capital World Group (CWG) implements a structured, multi-stage quality control system to maintain high standards throughout production. This standardized QC process monitors every critical step, from raw material inspection to final shipment, beginning with material quality control (Material QC).

1. Source inspections

Capital World Group begins quality assurance at the point of material receipt. All incoming fabrics and trims are inspected against approved specifications before being released to production. Fabric lab tests, colorfastness rub tests, and visual defect checks are conducted to identify risks such as shade variation, bleeding, or surface flaws.

This early-stage inspection ensures that only compliant materials enter the production line, preventing downstream quality issues and costly rework.

2. Fabric sourcing

During fabric sourcing, we verifie supplier documentation and material certifications, including organic, recycled, or sustainability claims when required by buyers. Test reports are collected and reviewed to confirm fabric composition, weight, durability, and performance standards.

Each fabric roll is checked for consistency with buyer-approved specifications, ensuring full alignment with technical sheets and reducing compliance risks in international markets.

3. Sample development QC

Create development samples that match all sizes and fit requirements. For example, when calculating how much fabrics is needed to make a jumpsuit, QC teams measure prototypes for correct measurements to confirm they comply with specified sizes and to have the correct amount of fabrics.

They also review stitching and construction details, securing pre-production approval. This step in the garment manufacturing process ensures any design issues are resolved before bulk production.

4. Inline QC

Inline quality control focuses on real-time monitoring throughout the sewing process. QC staff inspect semi-finished garments directly on the production line, checking workmanship, stitching consistency, seam alignment, and overall assembly quality.

By identifying defects early, we prevent error accumulation and ensure issues are corrected immediately. This proactive approach improves production efficiency, reduces waste, and supports stable output quality during high-volume orders.

5. Endline QC

Perform a thorough final inspection of finished garments. This quality audit includes a final measurement check, visual examination and a metal needle detector scan to ensure no broken needles remain in garments (a crucial safety step).

Inspectors also conduct physical tests on a sample from each batch to identify any defects with accessories like zippers, snaps, buttons, or elastic. Any garment failing these checks is pulled out or reworked.

6. Customer audits

Capital World Group actively supports customer audits and welcomes third-party inspectors for social compliance, ethical sourcing, or technical quality assessments. Many international buyers conduct on-site audits, which we facilitate transparently to demonstrate operational standards and manufacturing discipline.

These audits provide brands with added assurance of factory compliance, production capability, and the reliability of long-term partnerships.

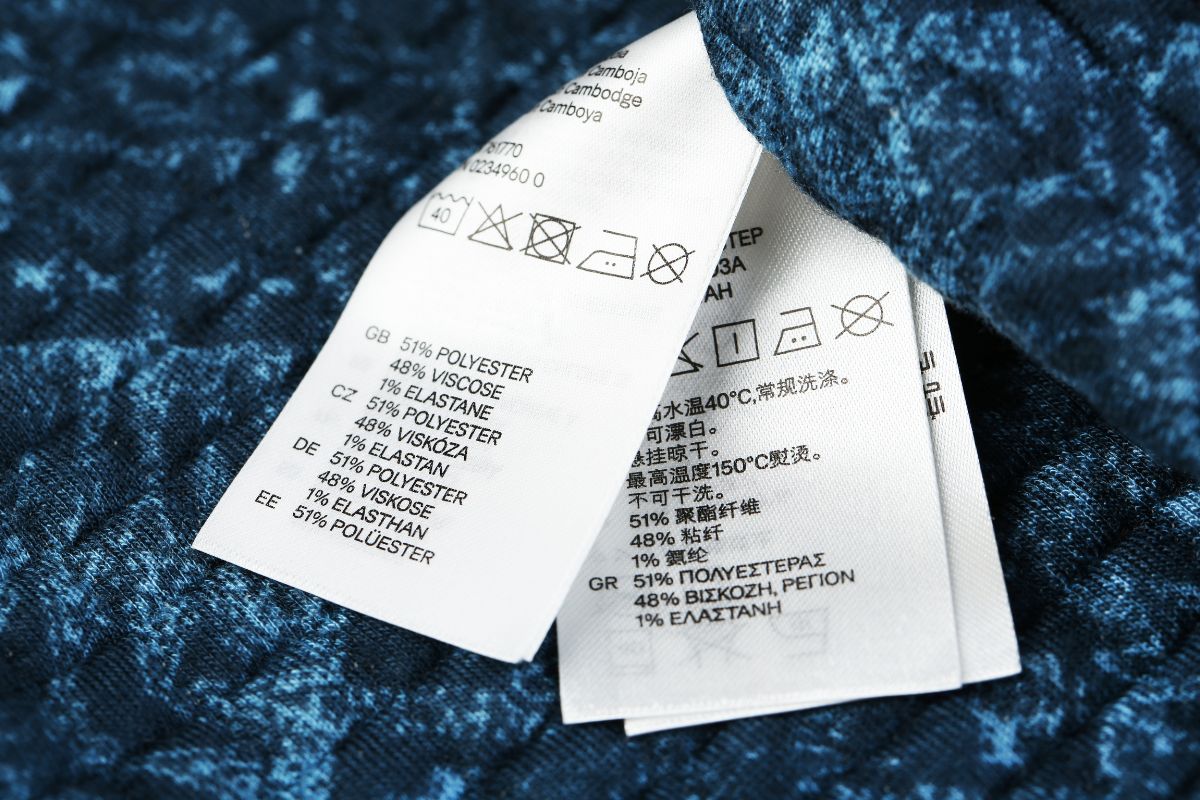

7. Label verification

Check that every garment’s labeling complies with the rules of its target market. This means verifying that tags clearly state the fibre composition, country of origin, manufacturer or importer information, size, and proper care guidance. Missing or inaccurate labels can trigger customs refusals or regulatory penalties.

8. Packaging inspection

Finally, verify that packing meets both client specifications and transit safety standards. Inspectors ensure the correct number of pieces and assortment are packed per carton, and that each shipping carton is of appropriate size, weight, and durability. They check that inner boxes or polybags are adequately sealed and that the carton protects the goods from damage.

If polybags are used, they must have the proper suffocation warning labels. A packaging check also confirms all shipping marks are correct, legible, and complete, including buyer name and PO, item description, carton count and dimensions, and country of origin.

Every detail is reviewed so that when goods depart the factory, they are retail-ready and compliant with import regulations when importing clothes from Vietnam to other countries.

Kiara Garments Factory of Capital World Group – a Vietnam garment manufacturer

Many brands struggle with delays, inconsistent sizing, and unclear compliance, but CWG solves this by combining certified processes with transparent operations, giving clients faster speed-to-market and dependable quality. Explore our homepage or contact us to see how we can deliver quality, consistency, and trust every step of the way.

One company is CWG’s Kiara Garments factory in Ninh Binh. This family-owned factory gives CWG end-to-end control from sourcing to export, operating 18 production lines with 800 skilled staff and specialising in manufacturing women’s tops and bottoms.