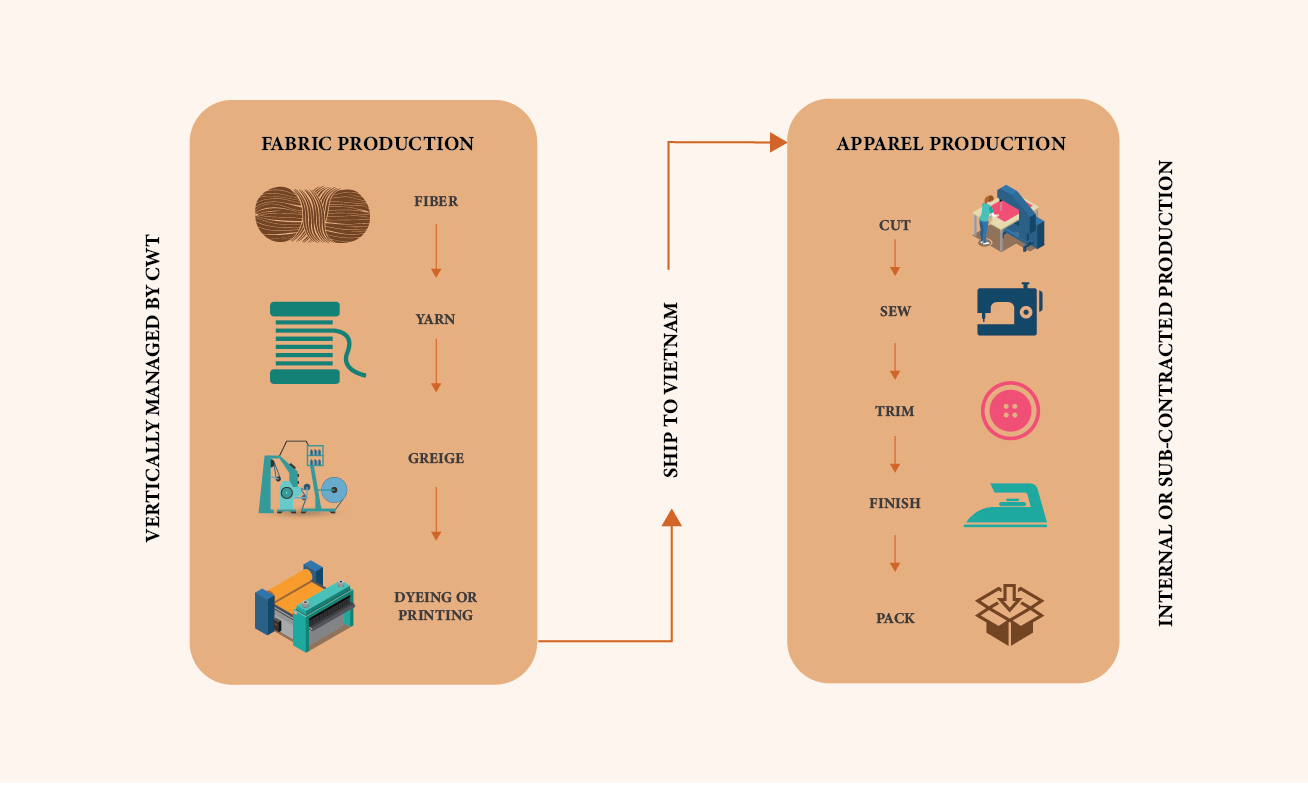

Vertically Integrated Manufacturing and Management

Vertical integration in apparel means controlling multiple stages of the value chain: design, fabric sourcing/production, cutting, sewing, finishing, QA, and logistics, under one group. In Vietnam, Capital World Group operates a fiber‑to‑fashion, full‑package (FPP) model that compresses timelines and improves quality consistency. With in‑house development, owned capacity, and in‑line QA/QC at each step, we deliver rapid sampling and predictable bulk production for ladieswear programs.

Our vertically integrated management and manufacturing model gives us a variety of advantages we gladly pass along to our partners/customers. As we have our hands in each step of the production chain, we add tremendous value by reducing cost, improving quality and efficiency while also having greater control, and most importantly, great flexibility.

Our fabric sourcing and production teams have deal with a large variety of fabrics and support our apparel teams with timely and quality raw materials. In order to ensure quality, we have a QA process at each step allowing us the ability to detect problems early and troubleshoot efficiently.

Capital World Group Vertically Integrated Manufacturing Process

Design & Development → Fabric sourcing/production → Cutting → Sewing → Finishing → QA/QC at each stage → Logistics

- Design & development: tech packs, pattern making, size sets.

- Fabric network: knitting/weaving, dyeing & finishing via partners in China/Taiwan/Vietnam with traceability.

- Cutting room: spreading, automatic cutting; needle policy in place.

- Sewing lines: 18 lines, ~800 operators, specialized in ladies’ knits & wovens.

- Finishing: washing/pressing, measurement checks, packing & cartonization.

- Logistics: consolidation for Hanoi/Hai Phong lanes; export documentation and Incoterms (FOB/CIF/DDP

Factory Capacity & Equipment

- Location: Nam Định, northern Vietnam (Red River Delta), with proximity to Hanoi and Hai Phong port.

- Lines & labor: 18 production lines, 800 staff, 50 merchandisers, 15 pattern makers, 20 sample operators, 15 QA personell

- Equipment: automatic spreader/cutter, overlock, coverstitch; needle detection at finishing.

- Categories: Ladies’ wear in both knits and wovens, including tops, blouses, dresses, pants, skirts, shorts, jumpsuits, and more.

Sustainability & Compliance

The Higg Index is an apparel and footwear industry self-assessment standard for assessing environmental and social sustainability throughout the supply chain. Launched in 2012, it was developed by the Sustainable Apparel Coalition, a nonprofit organization founded by a group of fashion companies, the United States government Environmental Protection Agency, and other nonprofit entities. We have been a proud member since 2019 – Capital World Group’s Higg ID is 132290

BSCI or Business Social Compliance Initiative run by Amfori – is a widely accepted social compliance standard mainly in the EU, however it is widely recognized as a high-standard social audit methodology and report. We have been a proud member since 2018 and our DBID is 372005.

A non-profit multi-stakeholder initiative that aims to eliminate audit fatigue in global supply chains. It provide the tools and system for a high-quality comparable data set on working conditions that can be used by all industry stakeholders, ultimately allowing users to redeploy resources into improving working conditions. Our SLCP ID is FA 154904.

We also welcome customers that prefer to carry out their own audits for social or technical purposes. We currently have valid audit reports from the following customers: